First of all, we need to know that the maintenance of pedestrian access gates (tripod turnstile, flap barrier gates, swing barrier gates, full-height turnstiles, and speed gates) is very important. Like cars, Pedestrian gates (tripod turnstile, flap barrier gates, swing barrier gates, full-height turnstiles, and speed gates) maintenance directly affect the service life of the turnstiles, so the pedestrian access turnstiles should be regularly maintained, not only must be done, but also according to the requirements. Many users rarely maintain or even do no maintenance at all. When the machine is broken, they only think of the manufacturer and replace the parts. This is often caused by small losses, and there is no maintenance at all at ordinary times. A little small problem will affect the use after a long time. Therefore, we must understand the importance of gate maintenance. Maintenance starts from the following aspects.

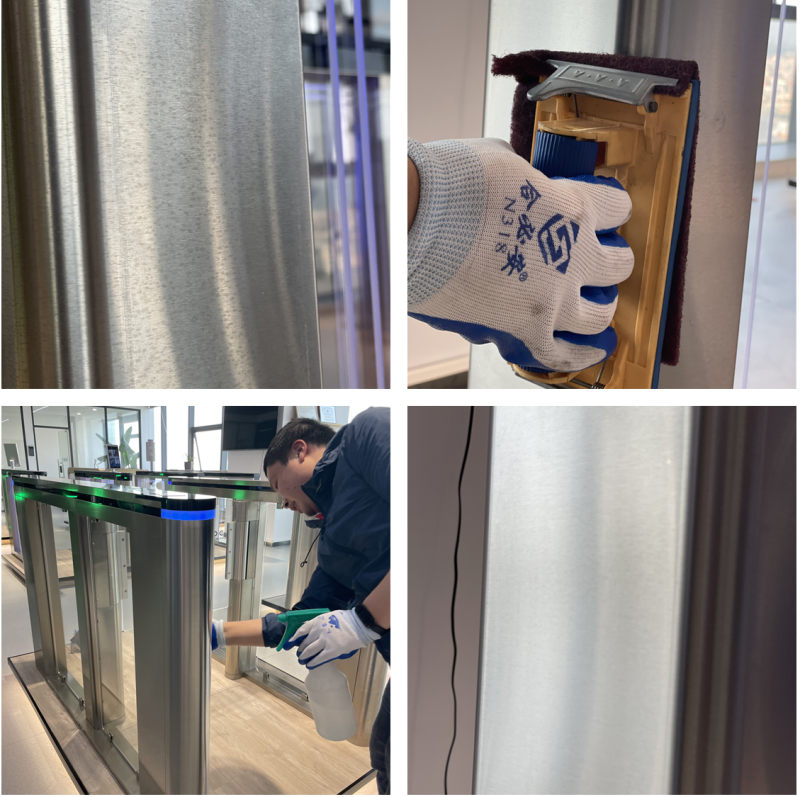

1. External cleaning and maintenance General pedestrian gates (tripod turnstile, flap barrier gates, swing barrier gates, full-height turnstiles, and speed gates) are made of domestic 304 stainless steel, and it is recommended to clean the exterior once a week.

1. Surface cleaning of pedestrian access gates (three-roller gates, wing gates, swing gates, full-height turnstiles, speed gates, and translation gates): clean the surface dust with a soft cloth, and polish the exterior of the chassis with a soft cloth and talcum powder , If conditions permit, you can apply anti-rust oil. Do not rub the newly-applied anti-rust oil by hand. Wait for about 3-5 hours to dry naturally before touching it, otherwise it will destroy the surface anti-rust effect.

2. Removal of rust spots on pedestrian access gates (three-roller gates, wing gates, swing gates, full-height turnstiles, speed gates, and translation gates): After a long time of use, especially when used outdoors, some rust spots may appear , To remove rust spots, you can use sandpaper and talc to wipe along the long lines (to protect the direction of thick lines), otherwise it will affect the appearance.

3. If the case is sprayed or painted on the exterior, use a soft cloth to wipe off the dust on the exterior. If there are any exposed scratches, use the same color paint to make up, but be careful not to put the wing gates, swing gates, and speed gates against the infrared rays. The shooting eye part is painted, otherwise the turnstile will falsely alarm and cause unnecessary trouble.

2. Maintenance of the movement: The movement is the heart of the machine and must be well maintained. It is recommended to maintain it once a month.

1. Cut off the power supply, open the cover of the pedestrian gate (three-roller gate, wing gate, swing gate, full-height turnstile, speed gate, translation gate), clean the surface dust, clean the transmission part first and then add butter, wing gate The gears and wheel grooves of gates, swing gates, speed gates, and translation gates should also be properly greased.

2. Check whether the fasteners and connecting rods are loose, and tighten them.

3. Check the wear of the wearing parts. If there is a gap of more than 3mm between the positioning arm and the positioning plate of the three-roll gate, replace it in time. If the gap is normal (1-1.5mm), add butter to the solenoid valve spool to keep the solenoid valve in place. When moving from side to side, reduce resistance and get lubrication. Be careful not to add too much, but in moderation.

4. Be careful not to adjust the limit switch and limit piece of the three-roller gate machine casually, in order to prevent errors from being adjusted too far or too close.

3. Pedestrian passage gates (three-roller gates, wing gates, swing gates, full-height turnstiles, speed gates, translation gates) circuit power maintenance

1. Cut off the power supply and clean the surface dust. Be careful not to wash with water to prevent short circuit.

2. According to the previous use, see if there is any problem in the circuit part. If there is no problem, check whether the circuit, power supply, wire, and each plug-in are exposed or loose, wrap and arrange them, tighten the plug-in, and check whether there is any leakage. Aging should be replaced.

3. Refer to the gate manual to check whether the parameters of each part are normal and whether there are aging electronic components. If there is a problem, contact the manufacturer, follow the clues, find the root cause of the problem, and replace individual electronic components.

4. The above maintenance must be maintained by special personnel, especially the maintenance of the movement and circuit parts, which must be professionally trained by Guangdong Lide Intelligence Technology CO, LTD and can only operate on the job with a full understanding of strong and weak currents.

Leave A Message

Leave A MessageIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.